NEWS

Miri, Sarawak

We have previously touched on what structural steel are and what they are used for. As structural steel has its many uses, it also means you have to have steel maintenance and upkeep.

When people talk about steel maintenance, they refer to the maintenance standard by the British’s “Glossary of General Terms Used in Maintenance Organization”. In short, they call it “glossary of Maintenance Terminology. Here are what it entails:

The combination of (all technical and assorted administrative actions) any action carried out to retain an item in order or restore it to a state in which it can perform its required function.

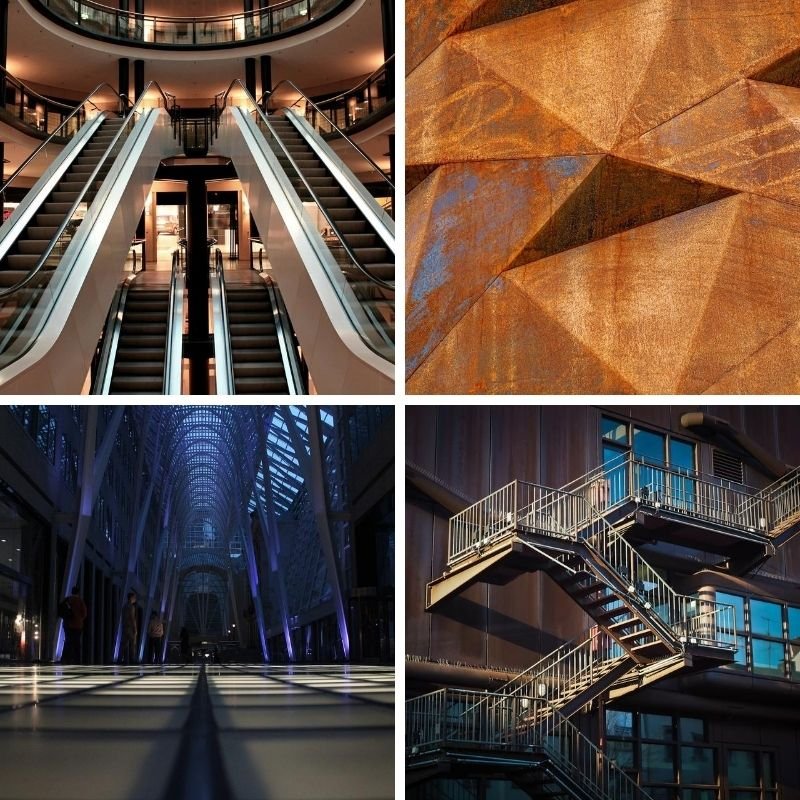

Structural Steel and Its Holistic Uses

Steel is definitely one of the strongest materials you can ever use for your buildings and structures. You can commonly find it in just about any building structures. You can even find it in your regular everyday household items too.

Steel can resist wind due to its ductility; it can bend without breaking. Steel material can endure forces up to 150MPH without sustaining damage to the exterior or foundation.

It can also absorb more energy than materials that are less sturdy. However, it does not attract lightning any more readily than it can attract other natural “act of god” disasters.

Even if, let’s say, lighting strikes a steel building or roof. The damage is pretty much minimal due to the lower electrical resistance steels spread. Its lower resistance of steel spreads the heat of strike along the roof and walls to be grounded in the earth.

Steel can also protect people and properties within the building (including electronic appliances and devices) from the effects of a lightning strike.

Steel structures can remain standing in seismic zone 4. It’s the highest classification of the seismic zone that are most prone to seismic waves and shifting grounds.

Cleaning and Maintaining Steel Products

It is without an inch of a doubt that (stainless) steel products are very useful for many industries. For example, steel 316 itself is used for lab equipment, jet engines, food and drug procession, boat fittings, and chemical containers.

Those kinds of steels are resistant to corrosion, highly durable, and easily manipulated. Furthermore, they are also quite simple and easy to maintain. You are able to keep steel beams and steel products strong and sturdy for many years to come. With the right set of tools, follow these simple steps to clean and care for your steel no matter what your industry is.

Why Have Steel Maintenance?

Steel maintenance generally comes hand in hand with building maintenance. That is where work is undertaken to keep, restore, or improve every facility in every part of a building. The parts include the services and surround a currently acceptable standard and to sustain the utility and value of a property.

Maintenance work aims to preserve the operating condition of machinery and building services, structures, etc. Building maintenance helps (in some ways) to restore the building to its original standards.

It also helps with improving the facilities depending on the development that is taking place in the relevant engineering specs.

A building, for obvious reasons, is exposed to weathering and is used for all kinds of possible purposes. Furthermore, there will be various agents within the building to invite damages and decaying agencies to act. Decay leads to damage, and damage invites further decay. More decay leads to more damages, which can ultimately lead to an unserviceable and dilapidated structure.

Types of Steel Maintenance

As steel maintenance comes after building maintenance, it comes under 3 categories. The categories are as follows.

Routine Maintenance

It’s good to have frequent and routine maintenance of the structure. The maintenance is important to keep it working and prevent it from early decay. A lot of buildings are made of different parts and from different materials in different locations/

They are all prone to natural decay because of steel ageing. While designing the building, it’s normal for architects and engineers to keep in mind the material ages. For example, a timber product material that is coupled with steel material has to be painted at regular intermissions.

Because of that assumption, timber material can lose up to 40% of its strength after 50 years+. If the timber attached to the steel parts are not properly maintained, then the timber part may show early signs of decay. Its strength may not last up to 50 years and beyond.

That means it is good to have routine maintenance. Routine maintenance includes cleaning, servicing, oiling, greasing, renewal of plastering, painting walls, woodworks, etc.

There are quite a number of items that fall under routine maintenance. Employed people within the building vicinities and engineers are expected to attend and keep track of the building’s overall structure safety. It’s best to be done daily, sometimes even weekly. All it matters is that as long as there is steel maintenance check-up at a regular interval so to keep the occupants of the building safe.

With all that being said, it’s good to maintain a regular routine maintenance post-construction. As the activity is needed to be attended for up-keeping of the building to counter-attack its early decay. It can cause severe damage to the building and prevent it from becoming non-functional.

Preventive Maintenance

Preventive maintenance basically talks about the activities that are essential to make the steel structures strong and sound. If it is, then it should be capable of resisting early decay or damage.

Preventive steel maintenance of a steel structure means improving on the quality of the construction. That way, it makes the building more durable and functional in the long run.

Sometimes it isn’t the post-construction phase that is the main contributing factor to the erosion of the building. During the construction phase, engineers have to investigate the soil, collect information about climatic condition of the site (eg; possible seismic danger, strengthening structures accordingly) against all possible future dangers, etc. All these fall under preventive maintenance action.

Unless the constructors collect that information and give the information to the designer, only then will the structure be safe. Otherwise, the structure will remain vulnerable from future disaster.

Remedial Maintenance

Despite taking on all likely preventive measures and providing routine maintenance, a structure will still undergo decay and damage. The building and its steel structure may still need upgrades and remedial measures.

Due to various contributing factors, the building’s steel structures can show signs of damage or distress. If the signs are showing already, it’s best to take actions for repairs or restoration work. Do not allow further damages to the structure by allowing the increase of possible steel structure defects.

As you take up repair works for the building, it’s good to locate and identify the location of the defect. Then only can the construction workers and engineers can rectify and fix the problematic areas. Random repairs of any problematic areas without identifying the cause can lead to serious damage in the foreseeable future.

Conclusion

The bottom line is that you have to keep the steel structures in check frequently. Less than frequent check-ups on the building’s infrastructure can have adverse effects on the building long term. Frequent check-ups mean fewer problems on the steel structures.